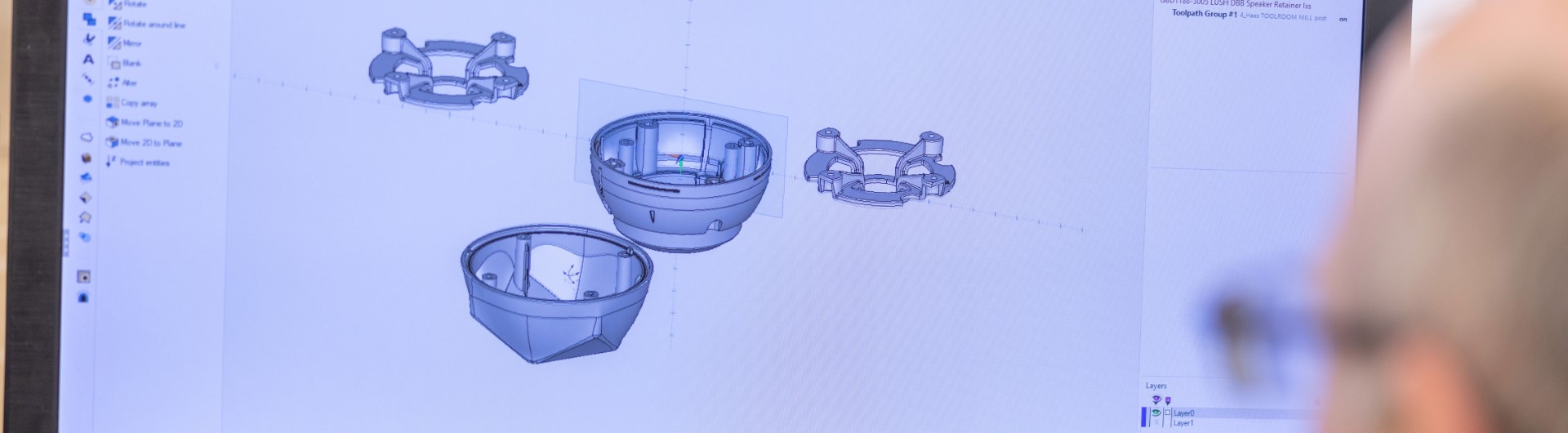

Design Support

Our engineering team provides comprehensive design support, helping you optimize your products for manufacturing efficiency and cost-effectiveness.

With DFM we can assist with:

- Design Review: Comprehensive analysis of your specifications and requirements

- Material Selection: Expert guidance on optimal materials for your application

- Virtual Prototyping: Advanced simulation to predict and prevent manufacturing issues

- Tooling Optimization: Strategic design of moulds for efficient production

- Process Validation: Thorough testing to ensure repeatable quality.